When it comes to operating complex industrial systems, the efficiency and reliability of your components can make or break productivity. One critical component is the gear pump—a vital part of many hydraulic and lubrication systems across industries. Whether your application lies in chemical processing, oil and gas, food manufacturing, or heavy machinery, choosing the right gear pump manufacturer is not a decision to take lightly.

In this guide, we’ll walk you through the most important factors to consider when selecting a gear pump manufacturer that aligns with your operational goals, safety requirements, and long-term ROI. We’ll also shed light on what makes gear oil pumps essential in industrial setups and how choosing wisely can impact system performance.

Understanding Gear Oil Pumps and Their Industrial Significance

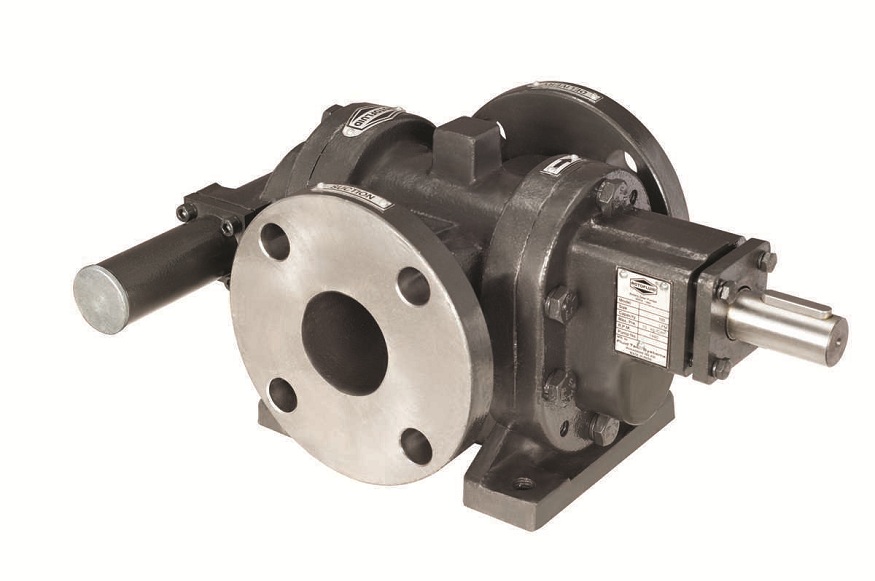

Before diving into selection criteria, it’s important to grasp what gear oil pumps are and why they’re so widely used. These positive displacement pumps utilize meshing gears to transfer fluids—typically oil—with precise volume control. Their rugged construction, high-pressure capabilities, and consistency make them a staple in lubrication circuits, fuel transfer systems, hydraulic units, and chemical dosing applications.

Key Advantages of Gear Oil Pumps:

- Steady and predictable fluid flow

- Compatibility with a variety of fluids, including viscous oils

- Simple design with minimal maintenance needs

- Reliable performance in high-pressure environments

This reliability underscores why finding a trusted gear pump manufacturer matters. The better the build and materials, the longer your systems will perform without failure.

Why Choosing the Right Gear Pump Manufacturer Matters

Not all gear pumps are created equal. Substandard materials, poor engineering, or lack of quality control can lead to frequent downtime, fluid leakage, and costly repairs. The right manufacturer offers more than just a product—they provide assurance, support, and adaptability.

1.Quality Assurance and Certifications

A trustworthy gear pump manufacturer adheres to strict quality standards. Look for companies that follow international certifications such as ISO 9001, API, or CE. These certifications ensure that each unit produced meets standardized quality and safety benchmarks.

Moreover, manufacturers with in-house testing protocols for flow rates, pressure, and temperature performance signal an extra layer of commitment to quality.

2. Industry Experience and Expertise

The industrial applications of gear oil pumps are diverse. Whether you’re in petrochemical processing or food-grade lubrication, the gear pump’s design must align with your specific use case. An experienced manufacturer will not only understand your industry’s requirements but will also offer guidance on the right materials (cast iron, stainless steel, bronze, etc.) and pump types (internal vs. external gear).

Ask potential manufacturers:

- How long have you been in the gear pump industry?

- Do you have clients in my sector?

- Can you customize pumps for specific applications?

Technical Support and Engineering Consultation

Beyond the pump itself, a good manufacturer provides valuable support both pre- and post-sale. This includes:

- System integration advice

- Custom engineering for unique setups

- Installation support

- Troubleshooting assistance

- Spare parts availability

If your operations demand consistent uptime, having a partner that responds quickly and knows your system is crucial. Choosing a manufacturer that offers 24/7 support or regional service centers can make all the difference.

Customization Capabilities

No two industrial systems are exactly alike. Flow rate, pressure range, fluid viscosity, operating temperature, and environmental factors all vary. The ideal gear pump manufacturer should offer customizable pump designs tailored to your project requirements.

Key areas to look for customization include:

- Mounting configuration

- Shaft orientation

- Material compatibility

- Seal type

- Drive options

Customization ensures that your gear oil pumps not only fit the system but also optimize its performance as well.

Reputation and Customer Feedback

Online reviews, industry forums, and client testimonials can provide insights that brochures won’t. Research how a manufacturer has delivered on past projects, especially for companies similar to yours.

Look out for feedback on:

- Delivery timelines

- Product reliability

- Customer service responsiveness

- Handling of warranty claims or defects

You may also ask the manufacturer to share case studies or references to validate their claims. The experiences of others can help you avoid potential pitfalls.

Price vs. Long-Term Value

Price is a factor, but it shouldn’t be the only one. The cheapest option might come with hidden costs—frequent repairs, inefficiency, or even complete system failure. Evaluate the total cost of ownership (TCO) instead. Consider the following:

- Energy efficiency of the pump

- Durability of materials used

- Maintenance intervals

- Warranty coverage

Reliable gear oil pumps may require a higher upfront investment, but the long-term value in productivity and reduced downtime typically offsets the cost.

Global Supply Chain and Logistics

In today’s interconnected world, choosing a manufacturer with global reach can be beneficial. Whether you’re planning expansion or need replacement parts quickly, a manufacturer with a broad distribution network can ensure quicker turnaround.

Factors to evaluate:

- Shipping lead times

- Availability of spare parts

- Local dealers or support centers

- Responsiveness during global supply chain disruptions

Sustainability and Environmental Responsibility

Increasingly, industries are leaning toward sustainable practices. Forward-thinking gear pump manufacturers are focusing on:

- Eco-friendly manufacturing processes

- Pumps designed for energy efficiency

- Use of recyclable or reduced-waste materials

If your organization is targeting sustainability goals, aligning with a manufacturer that shares your values can strengthen your brand’s integrity.

Red Flags to Watch Out For

While evaluating gear pump manufacturers, avoid falling into the trap of choosing based solely on appearance or promises. Here are some red flags:

- Vague or non-existent technical documentation

- Inconsistent product specifications

- No verifiable customer reviews

- Lack of warranty or after-sales service

- Overpromising without clear deliverables

Always trust but verify. A dependable gear pump manufacturer will be transparent and eager to demonstrate their capabilities.

Choose with Confidence

Choosing the right gear pump manufacturer is a strategic investment in your operational success. From ensuring smooth fluid transfer to preventing equipment failure, the quality of your gear oil pumps plays a pivotal role in overall efficiency.

By focusing on experience, customization, technical support, and a long-term value mindset, you can find a manufacturer that becomes a reliable partner—not just a supplier. Take your time, ask questions, and don’t hesitate to request technical consultations before making a decision.

Your operations deserve nothing less than a gear pump solution built to last.